Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

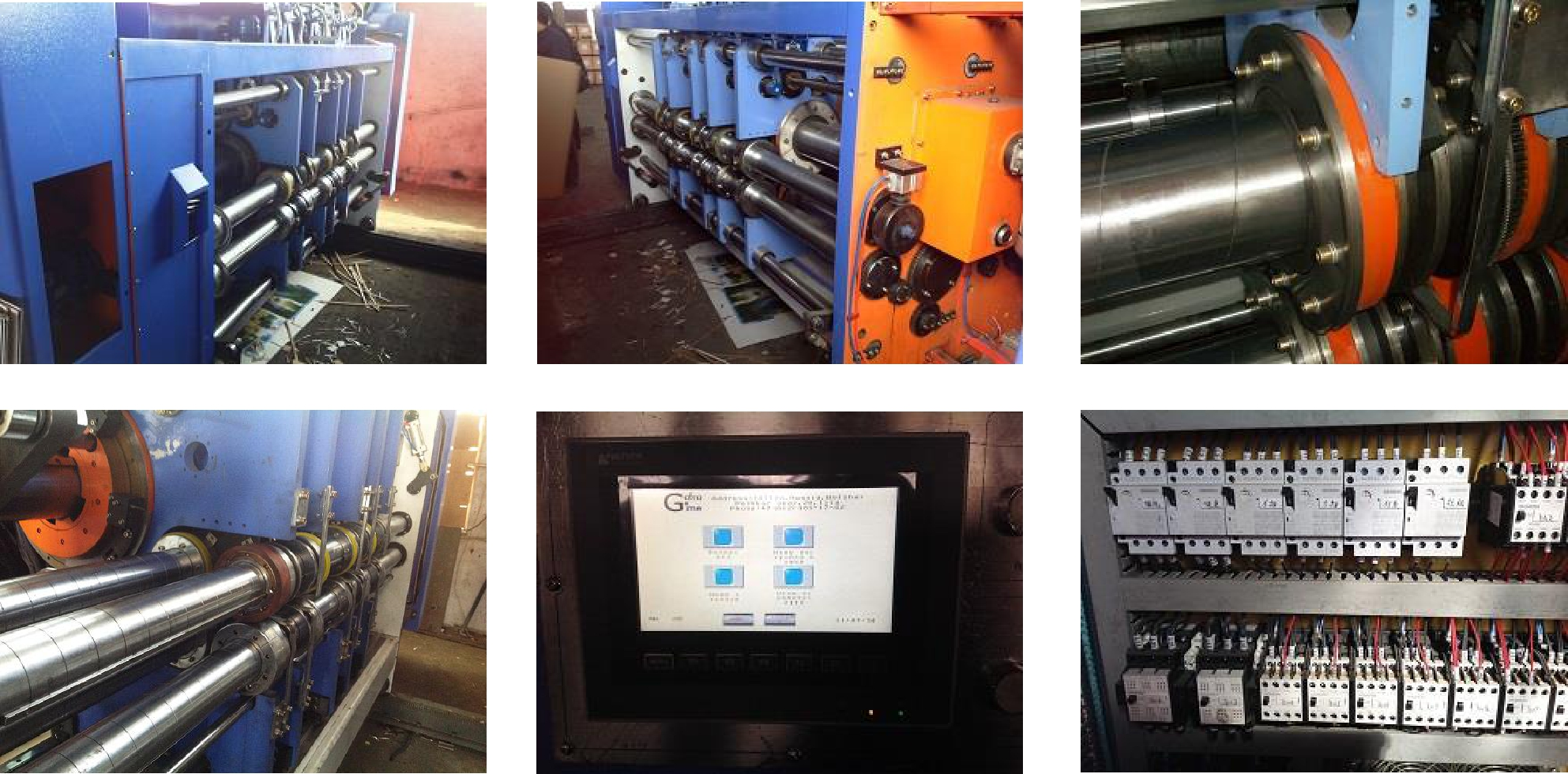

| Model No.: 6 | Brand: YUYUAN | Place of Origin: China |

|

Design speed

|

150(piece/min)

|

|

Economic speed

|

140(piece/min)

|

|

Inside wallboard width

|

2600mm

|

|

Max. Paperboard size

|

1200*2400mm/1200*2600mm

|

|

Min. Paperboard size

|

300x600mm

|

|

Max. Printing size

|

1200*2400mm

|

|

Max. Skip paper feeding size

|

1500*2400mm

|

|

Max. Die cutting size

|

1200*2400mm

|

|

Standard thickness of printing plate

|

7.2 mm (with version lining)

|

|

Carton precision

|

± 2mm

|

|

Weight approximately

|

33 tons

tons |

|

Overall dimensions

|

6600*5000*2500mm

(4 unit printers) 3500*14000mm (gluer) 2100*5600*1800mm (strapping machine) |

![]()